Table of Contents

- 1. What is Masterbatch?

- 2. How Masterbatch Works

- 3. Types of Masterbatch and Their Uses

- 4. Industrial Applications of Masterbatch

- 5. Key Benefits of Using Masterbatch

- 6. Charming Masterbatch: Innovative Color and Functional Solutions

- 7. Summary Table: Masterbatch Applications Overview

- 8. Frequently Asked Questions (FAQ)

- 9. References

1. What is Masterbatch?

Masterbatch is a concentrated mixture of pigments, additives, and carrier resins used to color plastics or provide specific functional properties. It is an essential material in the plastics industry, used to add color, improve performance, or provide protective qualities like UV resistance, flame retardancy, or antistatic features.

In simple terms, masterbatch acts as a coloring and performance enhancer for polymer-based materials, ensuring consistency, durability, and efficiency during plastic production.

2. How Masterbatch Works

Masterbatch is typically supplied in the form of small granules or pellets. During the plastic manufacturing process, these pellets are blended with the base polymer resin in a specific ratio, allowing the pigment and additives to disperse evenly.

- Step 1: The base resin and masterbatch are fed into the extruder or molding machine.

- Step 2: Heat and mechanical mixing disperse the additives and pigments uniformly.

- Step 3: The colored or modified plastic is extruded or molded into the desired shape.

This process ensures high-quality coloration and material performance with minimal pigment wastage compared to dry color methods.

3. Types of Masterbatch and Their Uses

Masterbatch can be categorized into two main types based on purpose: Color Masterbatch and Functional Masterbatch.

3.1 Color Masterbatch

Color Masterbatch is used to impart uniform color to plastic products. It contains pigments and dispersing agents that ensure stable coloration without compromising polymer integrity.

- Used in films, fibers, and injection-molded items.

- Provides UV resistance and aesthetic appeal.

- Customizable shades according to Pantone or RAL systems.

3.2 Functional Masterbatch

Functional Masterbatch adds specific properties to plastics beyond color. Common variants include:

- Antimicrobial Masterbatch: Prevents bacterial or fungal growth, ideal for medical and packaging use.

- Antistatic Masterbatch: Reduces static electricity in electronics and textile packaging.

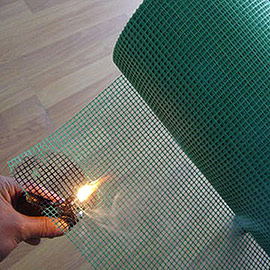

- Flame Retardant Masterbatch: Improves fire resistance in cables and construction materials.

- UV Stabilizer Masterbatch: Protects against UV degradation, extending outdoor product life.

4. Industrial Applications of Masterbatch

Masterbatch is used across multiple industries, including packaging, automotive, textiles, and construction. Each application benefits from its versatility and ability to customize material properties.

4.1 Packaging Industry

In plastic film and bag production, color masterbatch provides aesthetic branding while UV and antistatic masterbatch protect products from sunlight and dust attraction.

4.2 Automotive Industry

Car interiors, bumpers, and trims often require color consistency and enhanced durability. Flame retardant and UV stabilizer masterbatches are commonly used here.

4.3 Textile and Fiber Industry

Masterbatch is used in fiber spinning to add color and performance to fabrics. Antimicrobial masterbatch helps create odor-free, hygienic fabrics.

4.4 Construction Materials

Pipes, sheets, and cables made from plastic use functional masterbatch for UV protection, strength, and weather resistance.

4.5 Consumer Goods

Everyday items like bottles, toys, and containers use color masterbatch for consistent appearance and added safety through non-toxic pigments.

5. Key Benefits of Masterbatch and Their Uses

Masterbatch offers numerous advantages to manufacturers, making it an indispensable component of modern plastic production.

- Improved Color Consistency: Ensures uniform shade across all batches.

- Enhanced Performance: Adds mechanical strength, UV resistance, or anti-static properties.

- Reduced Waste: Easier handling and less pigment loss during mixing.

- Better Processability: Masterbatch helps improve melt flow and dispersion.

- Eco-Friendly Options: Some formulations use biodegradable or non-toxic carriers.

6. Charming Masterbatch: Innovative Color and Functional Solutions

Charming Masterbatch is a leading global manufacturer specializing in advanced color and functional masterbatch technologies. With decades of experience and state-of-the-art German twin-screw extruders, Charming has established itself as a reliable partner for clients seeking superior pigment dispersion and material performance.

6.1 Global Presence and Expertise

Charming’s products are widely used in China and exported to over 18 countries across Europe, South America, Southeast Asia, the Middle East, and North Africa. The company’s international recognition is built on its commitment to quality consistency, innovation, and personalized service.

6.2 Product Portfolio

- Color Masterbatch: Provides brilliant, consistent color for films, fibers, and plastics.

- Functional Masterbatch: Includes Antimicrobial, Antistatic, Flame Retardant, and UV Stabilizer solutions.

- Applications: Fiber/Filament BCF, Nonwoven, and Film/Plastic sectors.

6.3 Technical Support and R&D Cooperation

Beyond product supply, Charming offers complete technical support and customized development services to help clients solve practical production challenges and achieve creative breakthroughs.

The company’s philosophy centers on long-term partnerships — sharing technology, growing together, and creating sustainable success.

7. Summary Table: Masterbatch and Their Uses Overview

| Masterbatch Type | Main Function | Key Applications |

|---|---|---|

| Color Masterbatch | Coloration & Aesthetic enhancement | Packaging, Consumer Goods, Fibers |

| Antimicrobial Masterbatch | Prevents bacterial/fungal growth | Medical supplies, Food packaging, Textiles |

| Antistatic Masterbatch | Eliminates static buildup | Electronics packaging, Films, Automotive parts |

| Flame Retardant Masterbatch | Increases fire resistance | Construction materials, Cables, Vehicles |

| UV Stabilizer Masterbatch | Prevents UV degradation | Outdoor products, Pipes, Roofing sheets |

8. Frequently Asked Questions (FAQ)

1. How is masterbatch different from color powder?

Unlike color powder, masterbatch is a pre-dispersed form that ensures uniform color distribution, cleaner handling, and better stability during processing.

2. What percentage of masterbatch should I add?

The dosage typically ranges from 1% to 5%, depending on the desired color intensity or functionality.

3. Can Charming Masterbatch customize colors for my brand?

Yes, Charming offers custom color development based on Pantone or RAL codes, ensuring precise brand alignment.

4. Is masterbatch safe for food packaging?

Food-grade masterbatch formulations from reliable manufacturers like Charming comply with international safety standards and are safe for direct food contact.

5. How long does UV stabilizer masterbatch protection last?

It depends on product exposure and dosage, but typically provides 3–5 years of UV protection for outdoor applications.